Amphenol (Maryland), Inc.

Amphenol (Maryland), Inc.

8435 Progress Dr

Frederick 21701-4979

Vereinigte Staaten

Telefon+1 301-330-8811

Über uns

Wilcoxon Sensing Technologies, an Amphenol company, is a leading designer, manufacturer, and supplier of reliable, high-quality industrial accelerometers. Our vibration sensors are at work in predictive maintenance and condition monitoring programs around the world.

We design and manufacture a wide range of accelerometers, 4-20mA vibration transmitters, hazardous area sensors, handheld vibration analyzers, cable and connector assemblies, mounting accessories, industrial enclosures, and more. Our products are built to last, helping you effectively monitor rotating machinery in manufacturing and processing applications.

Our vibration sensors and new ultrasound monitoring solutions are essential to condition-based maintenance programs that save money, reduce downtime, and improve safety in plants worldwide. Applications include rail car monitoring, low- and high-speed machine tools, and general manufacturing that relies on rotating assets. Wilcoxon products are frequently used to minimize downtime and optimize maintenance in industries such as Food & Beverage manufacturing, steel and metal processing, Oil & Gas, cement manufacturing, and Pulp & Paper production.

Do your plant machines ever suffer from shaft misalignment, rotor imbalance, gear failures, or bearing faults? Have your operations ever experienced unplanned downtime that could have been avoided or prevented with condition monitoring? Vibration and ultrasound monitoring allow you to optimize lubrication, monitor machinery, diagnose developing faults early, and extend the life of production assets.

Unsere Produktgruppen

Keywords

- accelerometer

- vibration sensor

- vibration analyzer

- embeddable vibration sensor

- 4-20 mA vibration transmitters

Unsere Produkte

Industrial vibration sensors

Wilcoxon is your reliable source for a broad selection of high quality, long-lasting industrial accelerometers to monitor vibration. Maintenance and reliability professionals use our vibration for predictive maintenance and condition-based monitoring.

They are commonly used to monitor the condition of rotating machinery including motors, fans, pumps, gearboxes, blowers, machine tool spindles, compressors, chillers, rollers, and mixers. To cover this vast array of production assets, Wilcoxon manufactures a variety of IEPE accelerometers: general-purpose, high frequency, low frequency, high temperature, Intrinsically Safe and ATEX Zone 0/1, Class I Division 2 and ATEX Zone 2, dual-output of vibration and temperature, triaxial, velocity, high voltage isolation, radiation resistant, low power / low voltage, and underwater sensors.

Hazardous area accelerometers and vibration transmitters

Wilcoxon Sensing Technologies offers a large selection of hazardous area rated sensors for industrial condition-based maintenance and process monitoring. Our sensors can be installed in hazardous areas around the world in accordance with FM, CSA, ATEX, IECEx and other certifications.

- Intrinsically Safe IEPE accelerometers certified for operation in Class I Division 1 and ATEX Zone 0 / Zone 1 hazardous locations

- Class I Division 2 IEPE accelerometers certified for operation ATEX Zone 2 hazardous locations

- Intrinsically Safe 4-20 mA loop powered vibration sensors certified for operation in Class I Division 1 and ATEX Zone 0 / Zone 1 hazardous locations

- Explosion Proof 4-20 mA loop powered vibration transmitter sensors certified for use in potentially explosive atmospheres

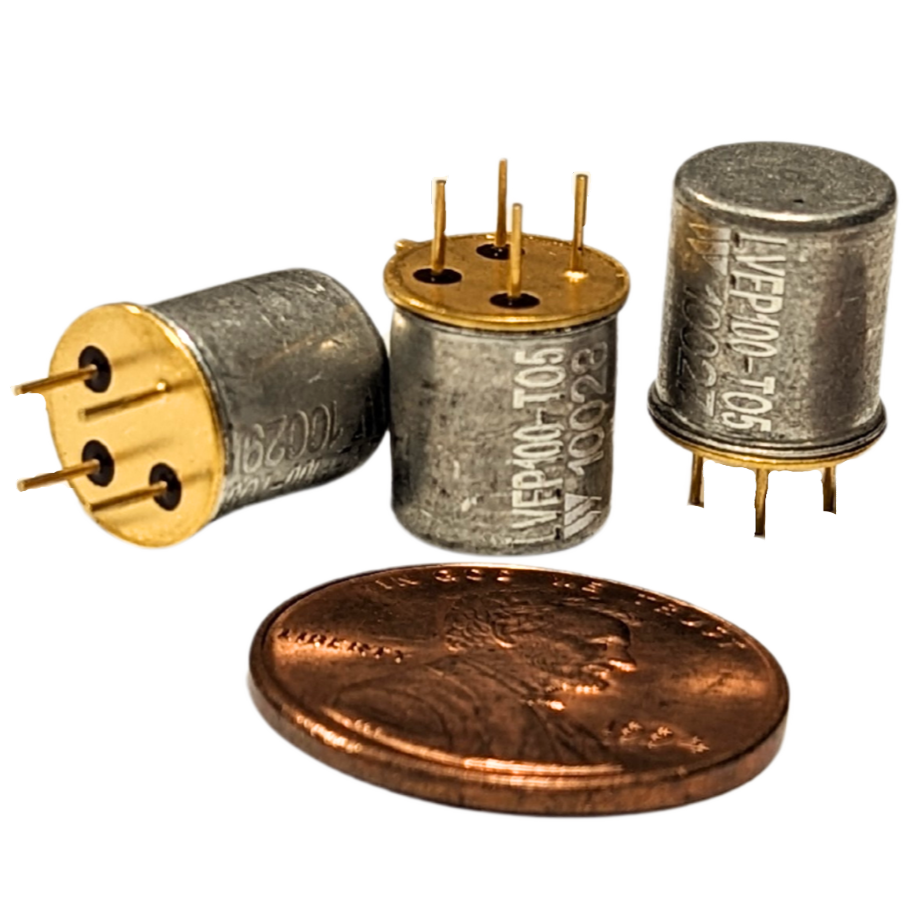

Ultra-low power embeddable accelerometers for wireless sensors and machinery self testing

The LVEP-TO5 is a high-performance piezoelectric accelerometer designed for ultra-low power consumption and easy integration into wireless accelerometers and other battery-powered applications. It is also easily integrated into rotating machinery for built-in self-test (BIST) capabilities. It has the full performance of an industrial accelerometer with the low power consumption of a MEMS accelerometer. Request a complementary demo unit for evaluation.

Key features and benefits

- Ultra-low power consumption to take more measurements using less battery, only uses 5% of the power of a traditional industrial accelerometer and lower power consumption than MEMS accelerometers

- TO-5 standard packaging to seamlessly integrate into the final design, small enough for 1- and 3-axis designs

- High performance sensing element to match the measurement capabilities required for effective machinery health monitoring

Applications for the LVEP050-TO5 accelerometer include wireless sensors, battery powered sensors, and sensors powered by energy harvesting.

It can be mounted inside motors, pumps, fans, vehicles, heavy equipment, conveyors, HVAC systems, and other production assets, to enable machinery self-diagnostics and asset monitoring via the Industrial Internet of Things (IIoT).

High performance accelerometer for machinery health monitoring

Like Wilcoxon’s industrial accelerometers, the LVEP050-TO5 was designed with the resolution (50 or 100 mV/g), frequency response (up to 12.5 kHz), and acceleration range (25 g) required for effective machinery health monitoring. Despite its small size and low voltage requirements, its performance matches that of a traditional industrial accelerometer.

Ultra-low power consumption

The LVEP-TO5 has an ultra-low power consumption of 180 µW, requiring a voltage source of 3.0 – 5.5 VDC, with a current draw of 60 µA when taking measurements (and no current draw in power down mode). The power-up and settling time is typically 350 µs.

Benefits of TO-5 packaging

The high-performance vibration sensor was packaged in a common TO-5 standard transistor canister for easy integration into sensors and production equipment.

- Good vibration coupling from the canister base into the vibration pellet is essential to effective machinery health monitoring

- Light weight preserves usable measurement bandwidth

- Hermetic sealing prevents contaminants and moisture from entering the sensor, to ensure stable measurements over a long operational lifetime

Vibration transmitters

Are you looking for cost-effective 24/7 vibration monitoring of your rotating machines as part of your condition monitoring and process automation program? Wilcoxon offers a broad selection of 4-20 mA loop powered sensors and vibration transmitters. They provide a 4-20 mA output signal proportional to the overall vibration level that is commonly accepted by process control systems such as a PLC, DCS or SCADA system. When trending indicates an increase in vibration levels, the raw vibration data can be accessed via a BNC connector on our intelligent transmitter for detailed vibration analysis and fault diagnosis.

Digital vibration monitoring solutions

Digital, IIoT, and AI-enablement solutions

- Digital triaxial accelerometers with temperature sensor

- Analog-to-digital converters for IEPE accelerometers

- Gateways and edge processing devices

Empowering organizations with data

- Utilize your vibration data for AI, machine learning training, and digital twin creation.

Maintain private and confidential control over your data, simplify network security and compliance. - Ensure compatibility with plant and enterprise data systems using our vendor-agnostic hardware.

- Take frequent measurements in extreme environments – without frequent battery changes.

Eliminate ongoing licensing fees and subscriptions with a one-time hardware investment.

Traditional condition monitoring systems, sensors, and software provide a robust monitoring solution for critical and essential plant equipment.

But their cost is often quite high. They are often too heavy (and prohibitively expensive) of a solution to justify deployment on “lower cost-of-failure assets”. As a result, many machines go unmonitored or are infrequently monitored using a route-based approach.

And proprietary systems have limitations. Data cannot be easily shared with other systems or processed externally for data science initiatives. To address these challenges, Wilcoxon is developing digital solutions to measure machine vibration and provide the data directly to an organization’s database.