SIKA Dr. Siebert & Kühn GmbH & Co. KG

Address

SIKA Dr. Siebert & Kühn GmbH & Co. KG

Struthweg 7-9

34260 Kaufungen

Germany

Telephone+49 5605 8030

Fax+49 5605 803555

Discover more from us

About us

SIKA Dr. Siebert & Kühn GmbH & Co. KG, based in Germany, is a manufacturer of high-quality solutions in the field of measurement and calibration technology.

Founded in 1901, the family firm develops and produces a wide range of products for conducting temperature, pressure and flow measurements. SIKA employs 400 staff across the globe and has subsidiaries and sales partners distributed across six continents.

Used by leading manufacturers worldwide, the sensors and calibrators can be found in products or production facilities of various industries such as HVAC.

SIKA is the inventor of industrial v-shaped thermometer and already has 50 years of experience in the mass production of flow and temperature sensors for traditional and environmentally friendly heating systems. We make efficient use of renewable energies.

Our product groups

Our application areas / Solutions

Downloads

Keywords

- Durchflusssensoren

- Temperaturmessung

- Kühlung von Rechenzentren

- Messtechnik

- Durchflussmessung

- Flow sensors

- Temperature measurement

- Measuring instruments

- Data Center Cooling

- Flow measurement

Our Products

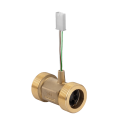

Flow Switches for Insertion Installation in Heat Pumps

SIKA flow switches are used for monitoring volumetric flows. Depending on the individual requirements, they are available for different nominal diameters and setpoint ranges. Thanks to the modular design, product versions and options for various applications can be set up. The further temperature and pressure ranges as well as the selection of materials or diverse connection options offer a high level of flexibility. Therefore, SIKA flow switches are used in many different areas:

- heating technology

- industrial cooling circuits

- water treatment

- potable water applications

The flow switch consists of a paddle system with a permanent magnet at the upper end. A reed contact is placed above this magnet outside the flow.

A second magnet is used to generate a restoring force for the paddle. When the flow to be monitored comes into contact with the paddle system, it is deflected. This causes the magnet to change its position relative to the reed contact, which is thus actuated. As soon as the flow is interrupted, the paddle moves back to its start position and actuates the reed contact again. The restoring force required for this is generated by the two repulsing magnets.

The utilization of the magnetic force, compared to a conventional leaf spring, results in significantly better long-term stability and much greater insensitivity to pressure peaks.

- insertion installation into copper pipes

- simple installation:

solder in a soldering adapter

insert O-ring

tighten union nut

- scope of delivery flow switch, O-ring and soldering adapter

- paddle lengths for copper pipe Ø 22…54

- easily distinguished by the colour of the union nut

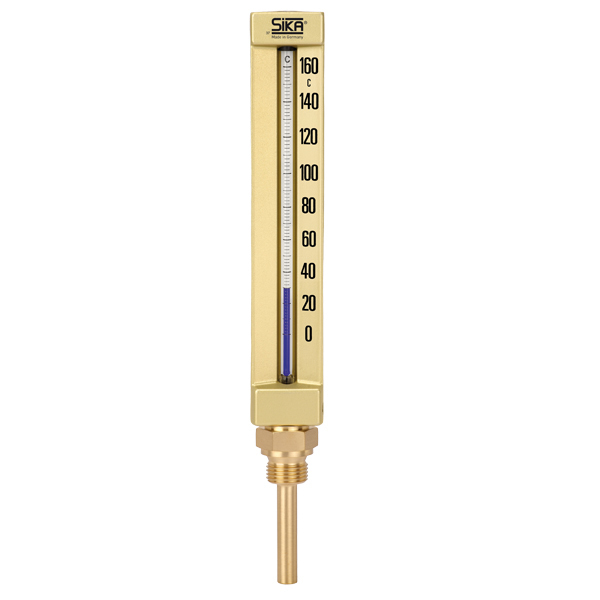

SIKA Thermometer for Heating

Since their invention, SIKA thermometers have been synonymous with robustness, reliability and accuracy. They contain the knowledge of many details and the experience from thousands of applications. This is why they have become indispensable in marine technology, mechanical and plant engineering as well as heating and air-conditioning technology. Over 15 million reliable temperature monitors have already been produced in Kaufungen.

The advantage of a glass thermometer over other thermometers (such as dial thermometers or digital thermometers) is obvious: no mechanically moving parts, no material fatigue, no electrical energy requirement, but very high accuracy and an extremely long service life. In other words, as long as a glass thermometer is not mechanically destroyed, it is accurate for life.

Thanks to their excellent workmanship, SIKA industrial thermometers have many advantages over thermometers from other manufacturers and can always be read precisely thanks to their high-quality housing finish, the indissolubly diffused scale imprint in the anodised layer and the indissolubly burnt-in graduation on the glass insert. Furthermore, the large measuring volume minimizes ambient temperature errors and the special manufacturing process reduces stresses in the glass. The high measuring accuracy, the use without electrical auxiliary energy as well as the high-precision individual piece testing are further special features of the SIKA industrial thermometer.

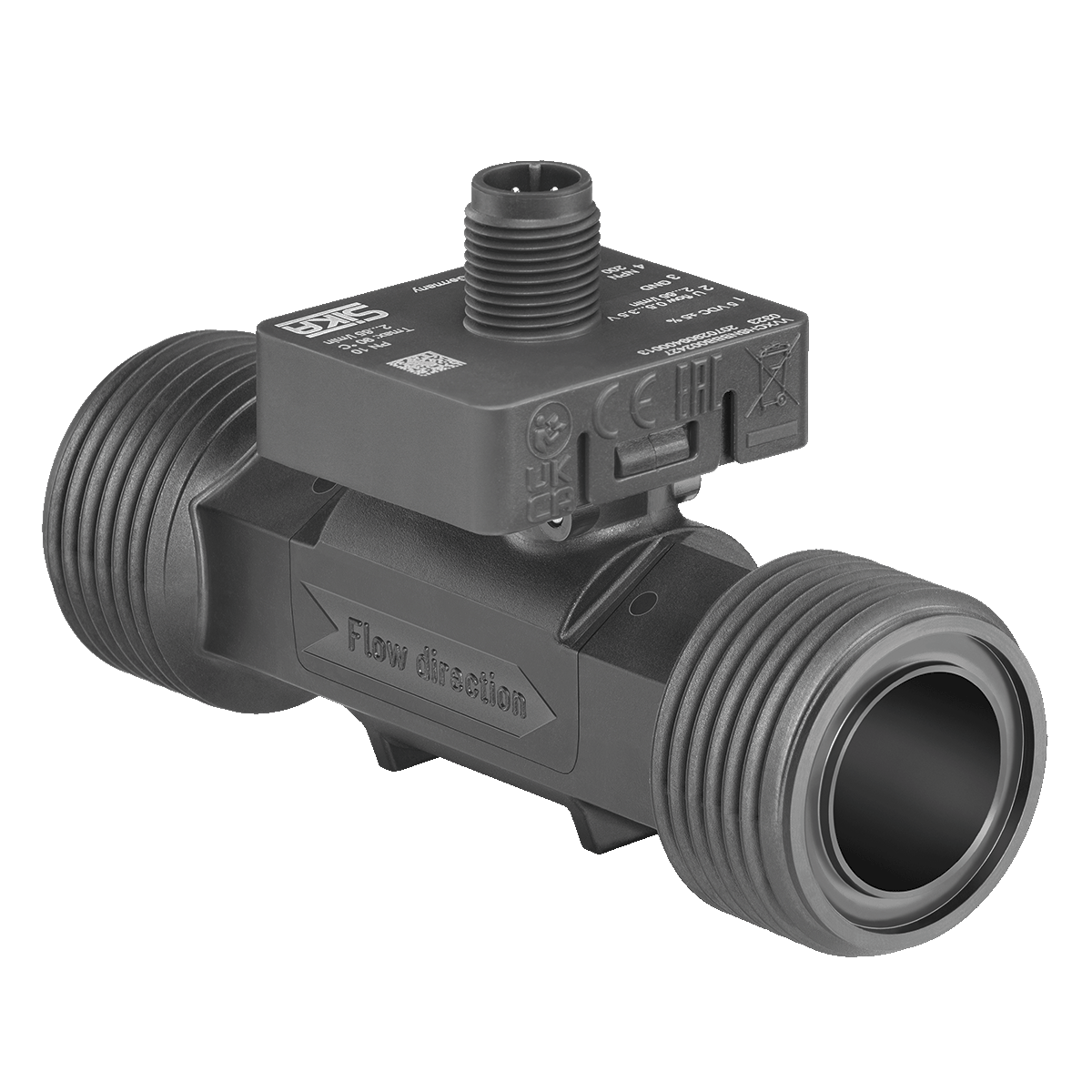

Vortex Flow Sensors for Heat Pumps

Alternate vortices rotating in opposite directions are generated behind a bluff body immersed in a flow. The vortices detach from the edges of the bluff body and form a Kármán vortex street in the fluid stream. The distance between the single vortices is constant. The frequency of the vortices flowing past a sensor depends on the flow rate and is proportional to the flow. The sensor detects these vortices which are then converted to an electrical frequency signal.

Some of the advantages of this measuring principle:

- Almost free pipe cross section > low pressure drop

- Wide range of applications in terms of pressure, temperature and density

- Independent of the conductivity of the medium

- High long-term stability / no zero drift

Our Vortex VVX series flow sensors offer the following compelling features:

- Solid state flow sensor with no moving parts for liquids → no mechanical wear

- Rugged glass fibre reinforced plastic ensures highest strength and performance

- Completely encapsulated piezoceramic sensor to detect the vortices → thus no direct contact with the medium

- Wide measuring span (1:20)

- Temperature sensor integrated

- Output signals: an analogue voltage signal and / or pulse signal is available for the flow, and a resistance or analogue signal is available for the temperature.

- High interference resistance

- Wetted parts metal-free

Highlights

- Increased efficiency of the heat pump by controlling even at low flow rates

- The low pressure drop of the sensor can help to reduce the power consumption of the pump

- The compact design allows the use even if only little space is available

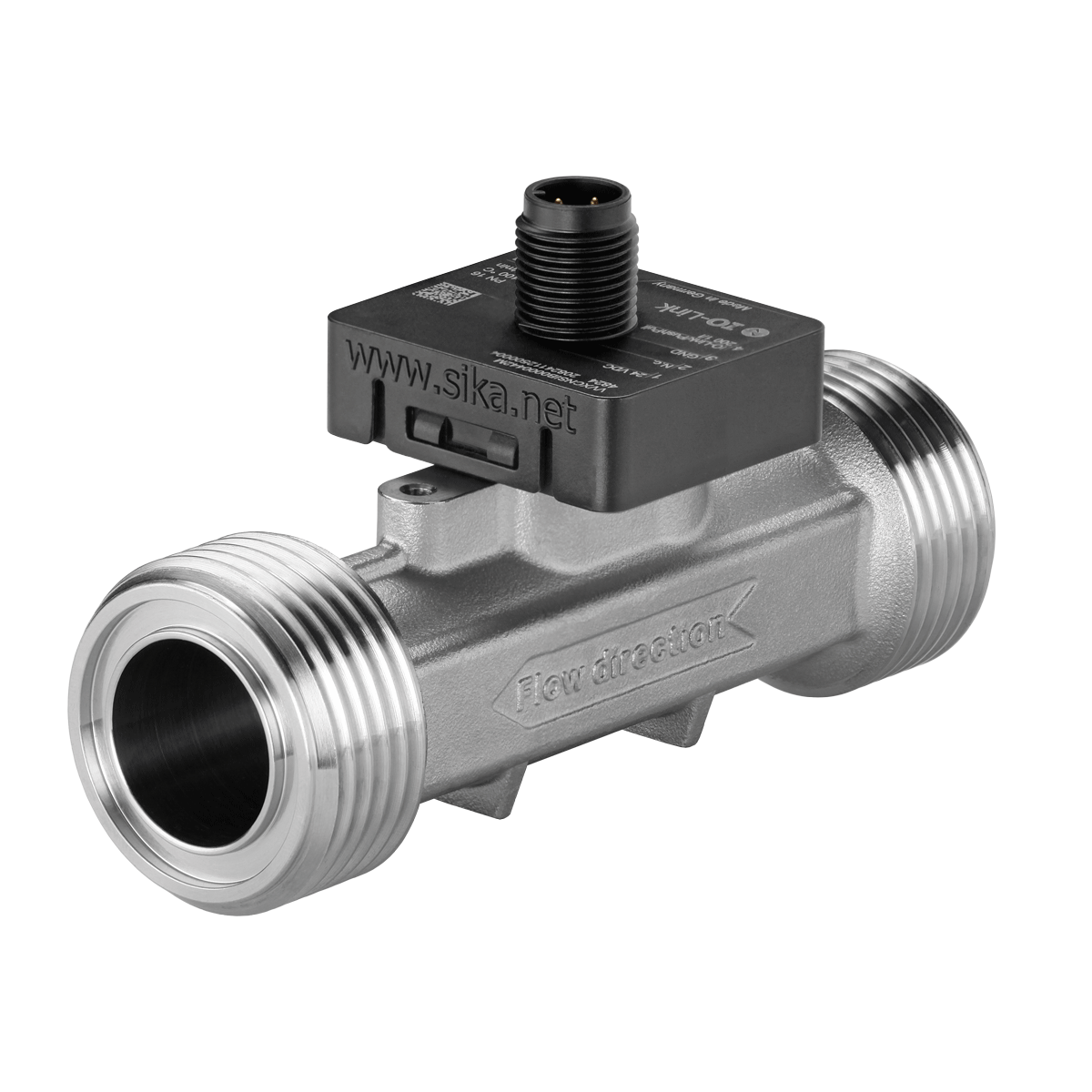

Vortex Flow Sensors Stainless steel for Data Center Cooling and Chilling

Alternate vortices rotating in opposite directions are generated behind a bluff body immersed in a flow. The vortices detach from the edges of the bluff body and form a Kármán vortex street in the fluid stream. The distance between the single vortices is constant. The frequency of the vortices flowing past a sensor depends on the flow rate and is proportional to the flow. The sensor detects these vortices which are then converted to an electrical frequency signal.

Some of the advantages of this measuring principle:

Available in nominal pipe sizes DN15, 20, 25, 32, 40. Multi-sensor for flow and temperature.

The advantages at a glance:

- Robust and durable: A complete series made of stainless steel

- Digital: Utilisation of the LIN bus digital communication system

- A tradition of quality: SIKA is recognised as one of the market leaders

- Extensive approvals: USANPT-approved & ETL/UL-approved, among others

- Capacity on demand: Thanks to production capacity, requirements can be met quickly

- Optimum turn-down ratio: Measuring span Tp 1:32

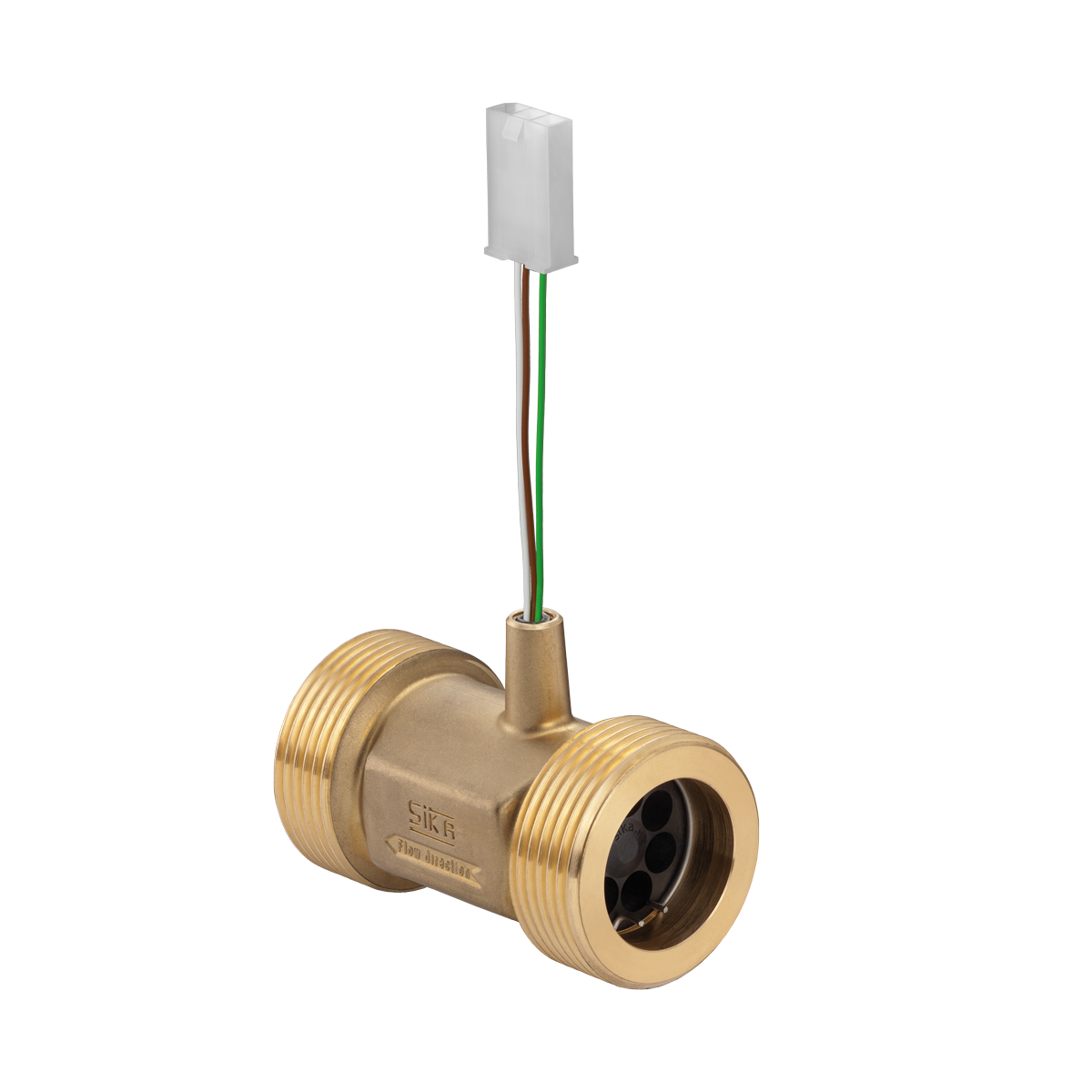

Turbine Flow Sensors for Fresh Water Stations and Heat Interface Units HIU

Turbine flow sensors of the VTY series have been specially developed for use in potable water series applications.

The sensors of the VTY series are used, among other things, for measuring potable water tap quantities.

The liquid flowing into the turbine flow sensor is divided into partial jets by the perforated disc. These hit the rotor uniformly and cause it to rotate. The rotor speed is now converted into an electrical pulse signal (frequency): The rotor is equipped with magnets, a Hall effect sensor detects the rotational movement.

A frequency signal (square wave signal) which is proportional to the flow is available.

Due to the uniform flow to the bearing, the forces largely cancel each other out and wear is reduced to a minimum. The extremely hard bearing materials, sapphire and hard metal, also guarantee an exceptional service life.

- Approved for drinking water

- Space-saving due to compact design

- low wear and extremely long service life due to high-quality bearings

- virtually no series dispersion due to fixed pulse rate

- wide measuring range (up to 1:90)

- insensitive to water hammers

- proven in numerous large series applications

- high measuring accuracy, largely independent of the installation position due to integrated flow straightener